During the summer of 2025, I was approached by Chris Myers, the professor of the Prototyping and Fabrication class at UC Berkeley, with an opportunity to design and fabricate the awards for the International Symposium on Academic Makerspaces (ISAM 2025). The conference was hosted by the Jacobs Institute for Design Innovation and organized by both Jacobs staff and the Higher Education Makerspaces Initiative. This project was commissioned outside of any class, with a defined budget, timeline, and set of deliverables.

I began the process by developing several design concepts through sketches, CAD models, and full-scale cardboard mockups. These were presented to the director of the Jacobs Institute and the conference organizers to review form and scale. While there were few hard constraints, the goal was to create an award that felt modern, intentional, and appropriate for a professional academic audience. There was also interest in incorporating local materials, which ultimately shaped the final design.

The finished awards pair locally sourced California redwood with laser-cut brushed stainless steel. The redwood provides warmth and regional context, while the steel adds contrast and precision. I was initially hesitant to use a softwood for an award, but reasoned that these objects would mostly live on shelves rather than be frequently handled, and the visual character of the material justified the tradeoff.

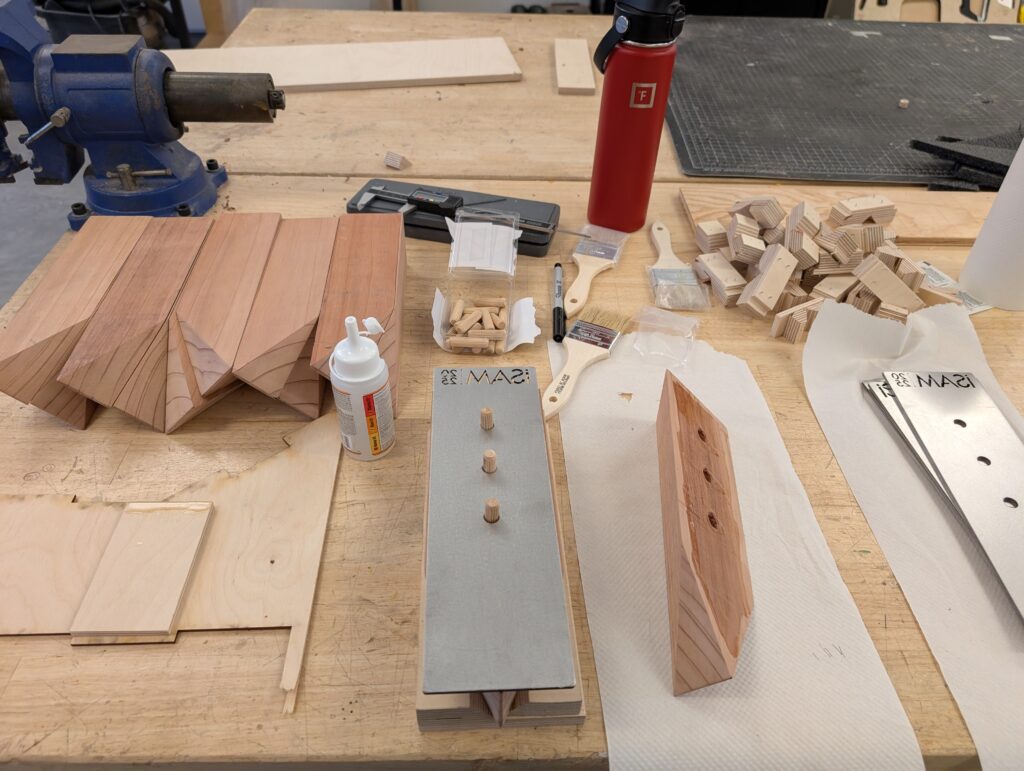

Fabrication was completed using tools at the Jacobs Makerspace. I processed 4×4 redwood posts by dimensioning them on the table saw, cutting compound angles on a radial arm saw, and sanding them precisely to final size. Two wood halves were glued together around the stainless steel insert, with dowel pins added late in the process to improve alignment and strength. This required careful layout and drilling to ensure the wood and metal registered cleanly. The angled bases proved to be one of the most demanding steps, as each cut needed to be executed in the correct orientation to maintain consistent geometry across all pieces. The awards were sanded to a high grit and finished with a low-gloss polyurethane.

In total, I produced nine primary wood-and-metal awards along with nine simpler bent-metal honorable mention awards, the latter added shortly before the conference. Because of the compressed timeline, I handled nearly all fabrication myself, with limited assistance from makerspace staff on laser cutting.

The awards were presented during the conference following a keynote by Adam Savage. I was unexpectedly invited on stage to display the awards while Chris introduced the project and described the process. Seeing the awards in context and seeing them handed to professional makers and researchers was a meaningful moment and a reminder of the importance of trusting finished work rather than fixating on minor imperfections. Later, I was featured alongside Adam Savage in a Berkeley Engineering Instagram post highlighting the event.

This project was a turning point for me as a designer and fabricator. With full control over the design, materials, schedule, and final quality, it pushed me to work at a higher level of precision and professionalism than typical class projects. More than anything, it reinforced the value of careful planning, disciplined time management, and treating fabrication as an exercise in craftsmanship.